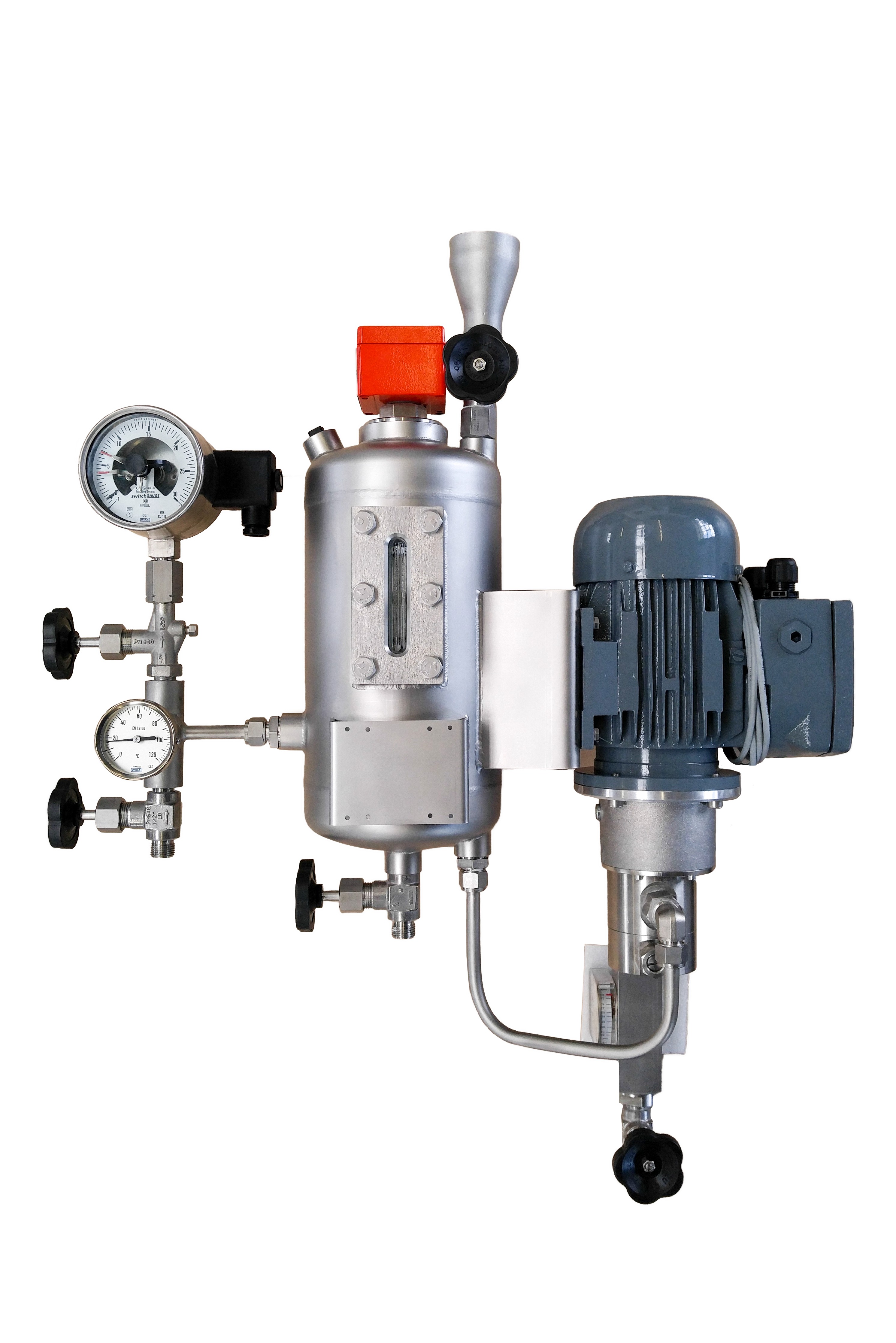

TSS-2000

Description

Features

With the TSS-2000 thermosiphon system, both double and tandem mechanical seals can be supplied in a wide range of applications. The sealing pressure containers are available in differnet sizes with dished bases, sight glasses for fill level monitoring and with or without cooling coil. All process connections and brackets are provided on the container as standard. All process connections can be implemented as flanges or sockets with/without sealing surfaces.

based on: API 682/ISO 21049: Plan 52/53A

Basic tasks

- pressurize the Buffer chamber

- leakage compensation

- barrier fluid is circulated

- cooling the seal

- selectively absorb product leakage

- Prevent dry running

Recommend applications

| Chemical industry | |

| Petrochemical Industry | |

| Oil und gas industry | |

| Refining technology |

Standards & approvals

- PED 2014/68/EU

- ASME VIII DIV. 1

- SELO

- TR-CU 032/2013

- KOSHA

- SANS 347:2012

| # | TSS-2030 | TSS-2031 | TSS-2060 | TSS-2061 | TSS-2090 | TSS-2091 | TSS-2120 | TSS-2121 |

|---|---|---|---|---|---|---|---|---|

| Volume(L) | 3 | 3 | 6 | 6 | 9 | 9 | 12 | 12 |

| Pressure (bar) | 25 | 25 | 25 | 25 | 25 | 25 | 16 | 16 |

| Temperature (°C) | -21..200 | -21..200 | -21..200 | -21..200 | -21..200 | -21..200 | -21..200 | -21..200 |

| Cooling coil | X | X | X | X | ||||

| Cooling capacity (kW) | 0,25 | 2 | 0,35 | 3 | 0,5 | 4 | 0,5 | 4 |

- Vessel: 1.4571 / 316Ti

- Sight glass: Borosilikat Reflex

- Seal: PTFE

1) The cooling capacity is depends on several factors, for a precise calculation please contact our technical Department.

| Datenblatt | |